DESCRIPTION

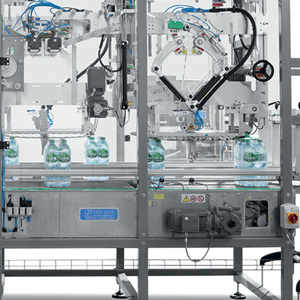

Compact and robust machine, with stainless steel frame structure and components suitable for working in aggressive environments, subject to frequent cleaning with corrosive products, in various sectors: food, beverage, cosmetics, chemical, etc.

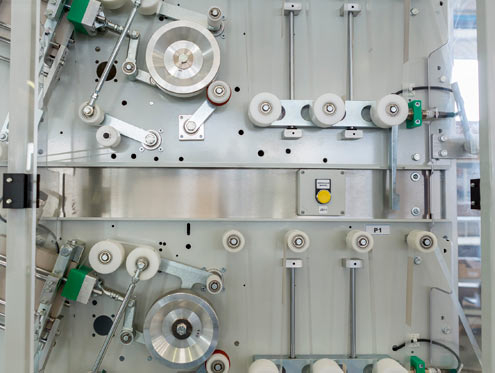

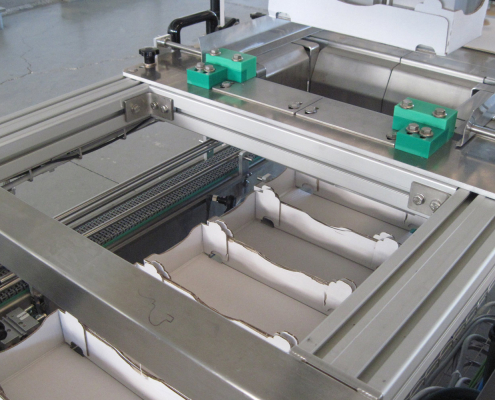

Integrated, dynamic, constant-pressure carton magazine with differentiated storage capacity according to the thickness and dimension of the carton, with automatic adjustment.

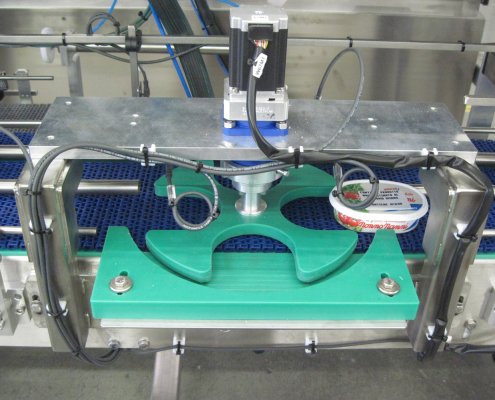

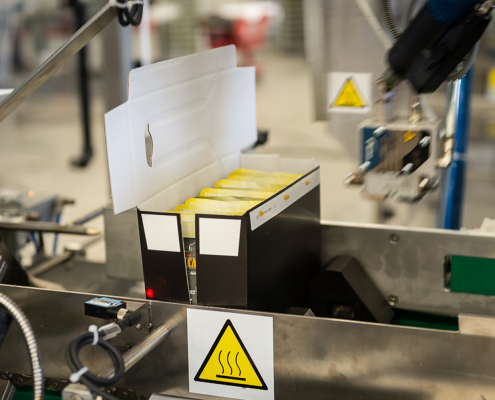

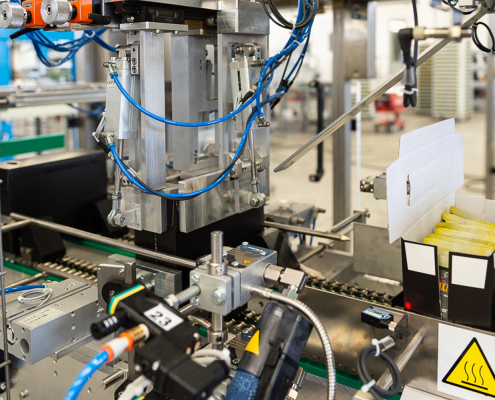

High precision hot glue application system even at high speed lines.

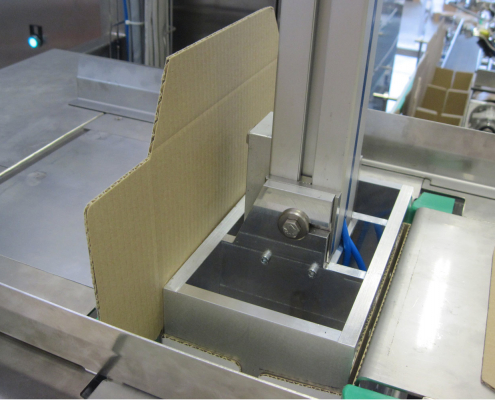

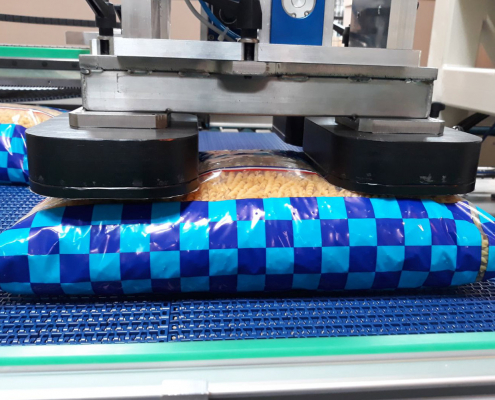

The formation of the TRAYS and WRAP AROUND can take place with:

- pressure matrix

- in continuous with the use of teeth chain, “U Shape” mode

Both mechanisms are calibrated for multi-format cartons, with automatic format change or through simple adjustments.

According to the product, the configuration required, and infeed into the machine, the products are grouped / stacked through different devices: dynamic motorized table; overturning system; through smart-track; in accumulation on conveyor belt; in multi-row with dividers; etc…

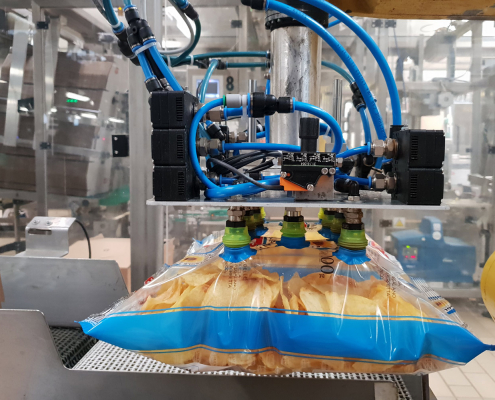

Robotized Pick & Place module for top-load or lateral-load product insertion with customized picking head according to product specifications: with single or multiple head, suction device, pressure head, mechanical grip.

In the same module, two or more Robots can cooperate, according to the production speed, the number of lines to manage and the complexity of the configuration to settle.

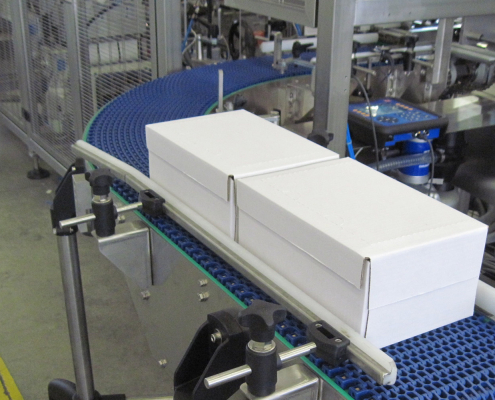

According to the TRAYS and the WRAP AROUND type of formation and filling, the Intralox motorized conveyors will feed in a fluid and dynamic way the products and the empty cartons at the machine infeed and the full cartons at the machine outfeed.

TECHNICAL DATAS

Maximum production speed: 25 tray/WA per minute

Compressed air: 6 bars

Power installed: 18 Kw

Tension: 400V

Frequency: 50 Hz

Noise level: dBA 76

Safety protection in polycarbonate, 15 mm thick as per CE Standard

MODELS

TPROT20 WA

TPROT20 TRAY

TPROB20 WA

TPROB20 TRAY

TP TRAY