DESCIPTION

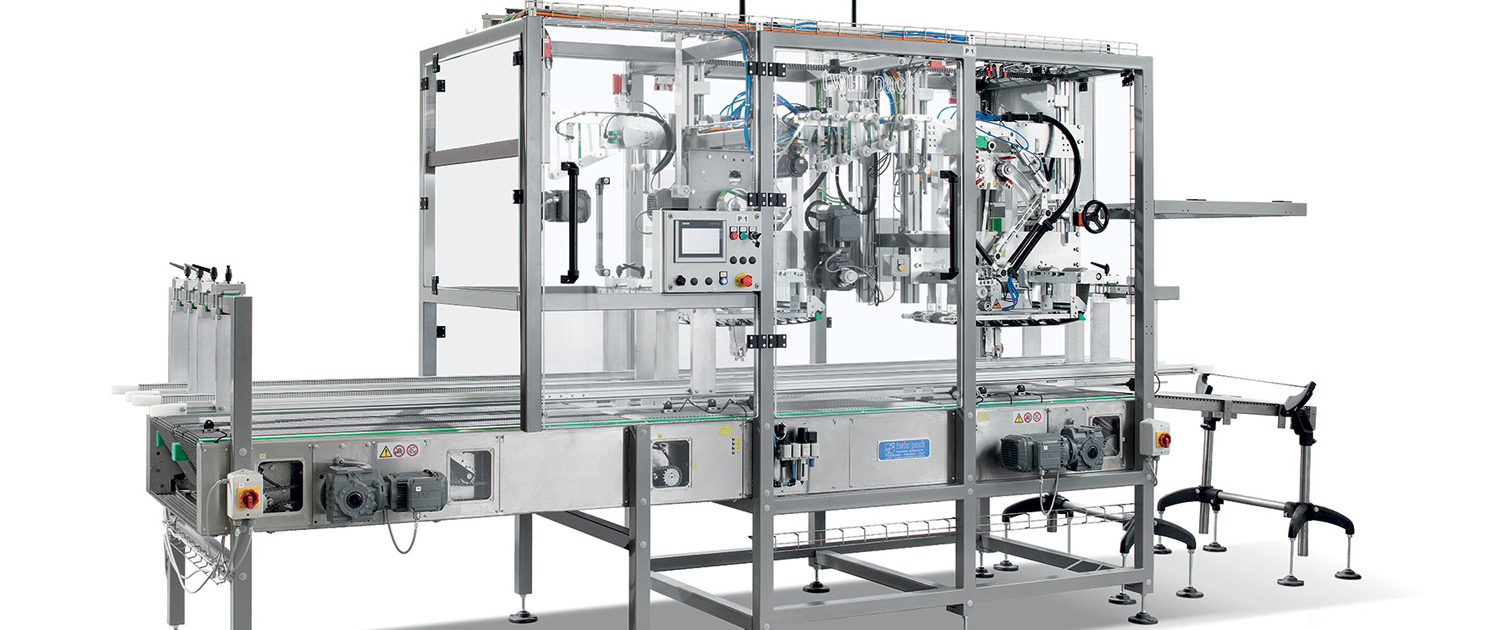

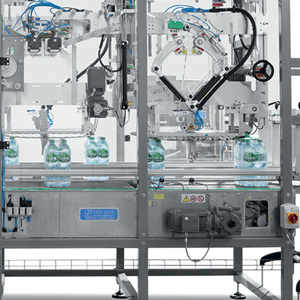

The electronic handle applicator is an high technological level product.

Compared to the traditional ones, it’s a revolution: the speed is considerably increased, the machine is much more versatile and it is able to work different packaging and product only by a software switch and none machine variation.

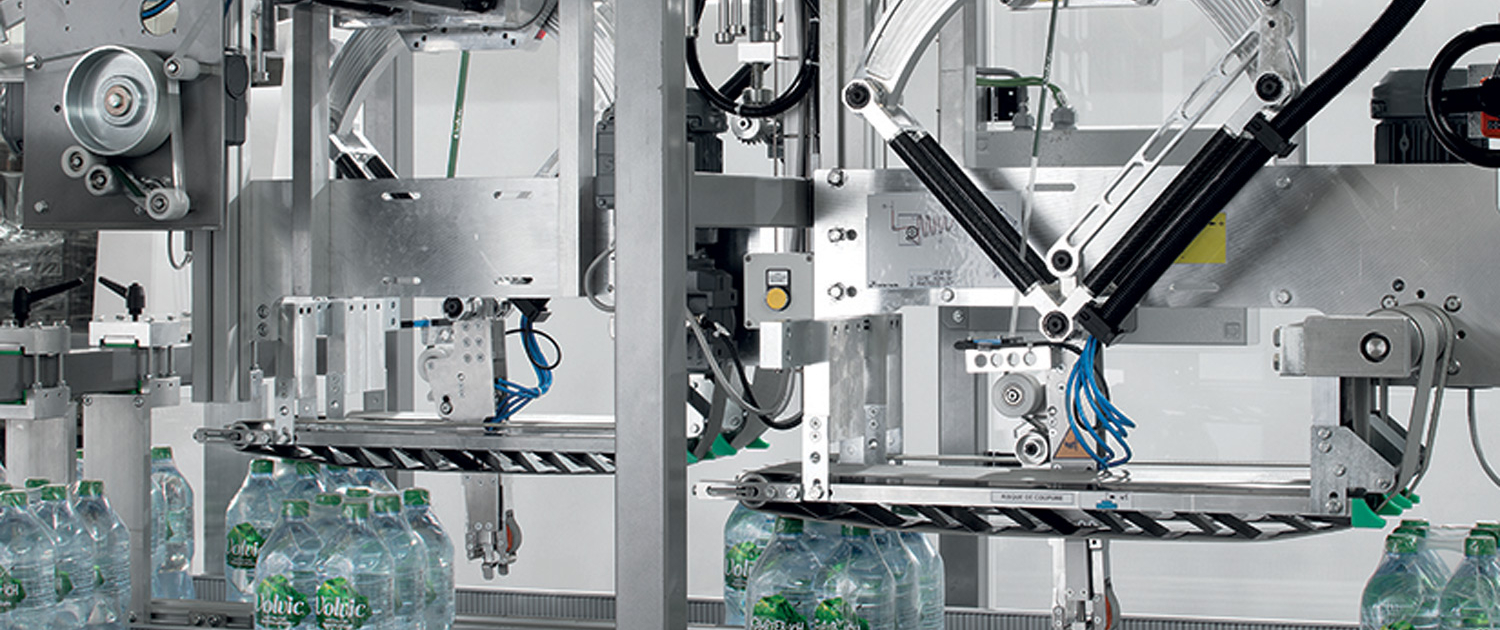

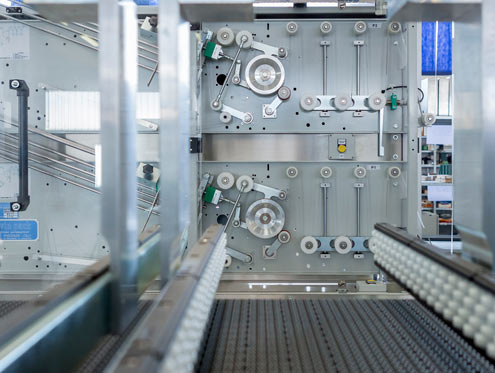

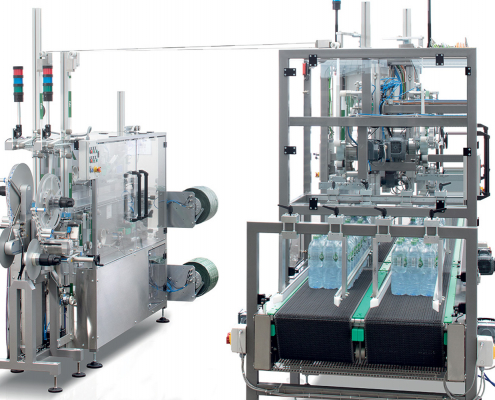

The packs arrive on the machine conveyor, and are then automatically slowed down and spaced via a series of Intralox conveyors.

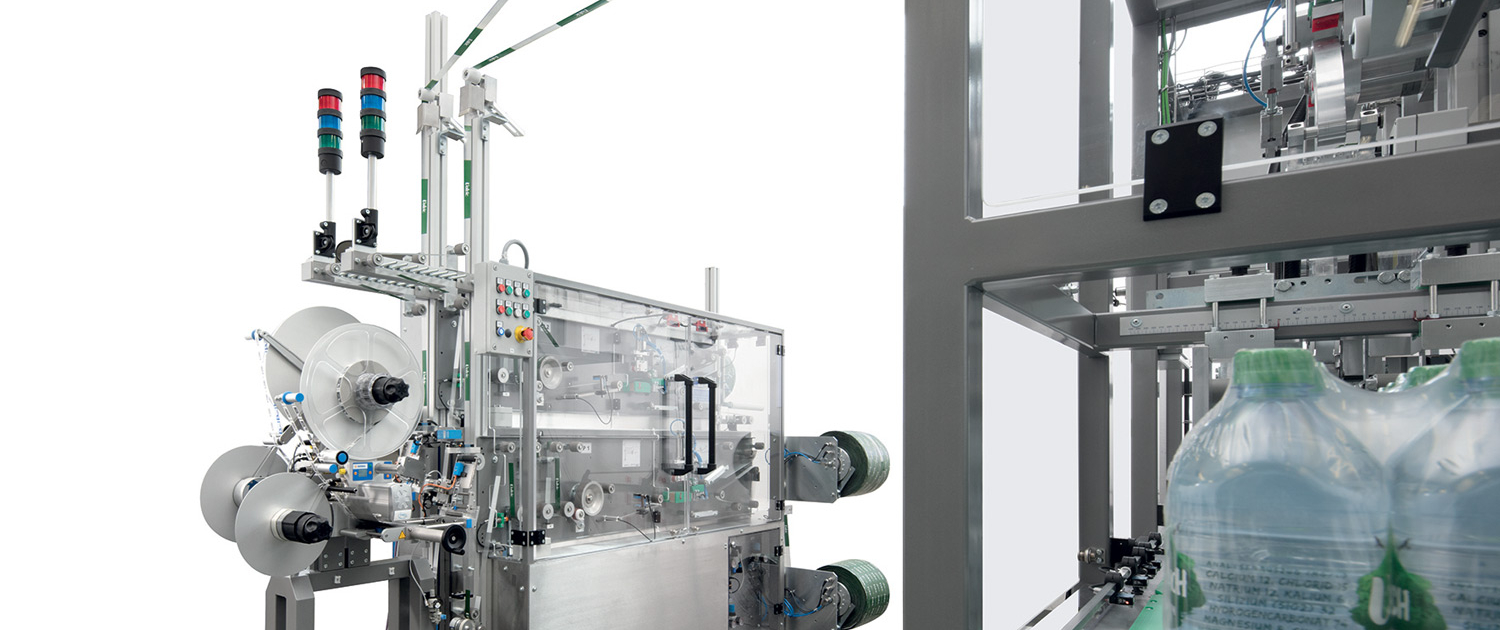

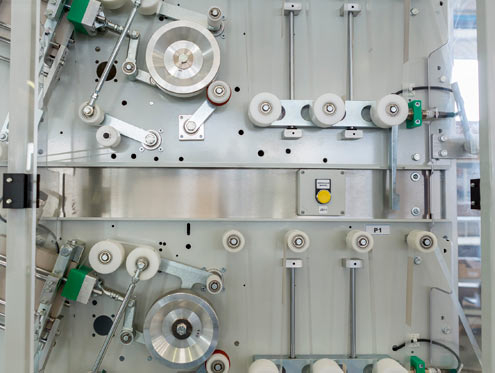

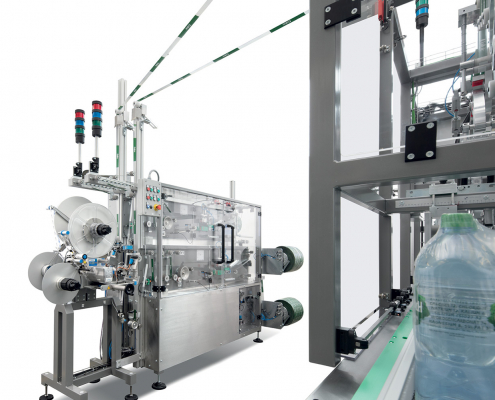

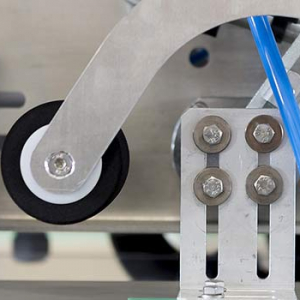

The adhesive tape is unwound by an electronically controlled motor-driven roller as a function of pack flow. Application of the cardboard (or other materials) on the adhesive is carried out continuously by a mechanical double cam system. The thus-obtained handles are continuously applied to the transiting clusters by an electronic mono-applicator head.

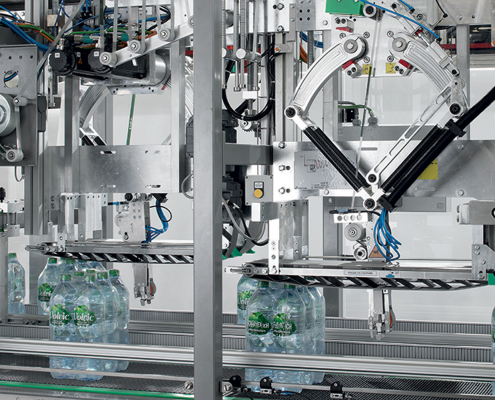

Handle application movement is fully controlled by electrical-axis servo motors. Each handle application cycle takes place within a space smaller than the inter-product gap, thus ensuring the system has excellent flexibility.

Depending on the product being processed, the machine can be equipped with the handle arch (optional) unit, a dynamic, mechanical, electronically synchronised system that operates during product/pack through-flow. Handle and cardboard alignment is electronic, allowing the machine to correct any errors autonomously via automatic repositioning.

The handle tape is made of transparent mono-oriented polypropylene coupled to cardboard (or other materials), which may be neutral, coloured or printed with promotional text and/or images.

Each head can be provided with a second reel holder for 5000-metre adhesive tape reels (optional).

TECHNICAL FEATURES

Max speed in single line: 120 ppm

Max speed in double line: 120+120 ppm

Max speed in triple line: 120+120+120 ppm

MODELS

Mod. M.D.E.-VHT

in single lane maximum working speed 100 per 1′ in single lane

Mod. M.E.T.E.-VHT

Maximum working speed 100 + 100 per 1′ in double lane

Mod. M.E.T.E.-VHT140

Maximum working speed 140 + 140 per 1′ in double lane

Mod. M.E.T.E.-V3HT

maximum working speed 120 + 120 + 120 per 1′ in triple lane