DESCRIPTION

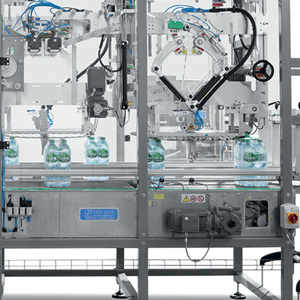

Automatic machine for the application of self-adhesive handles on a variety of clustered products.

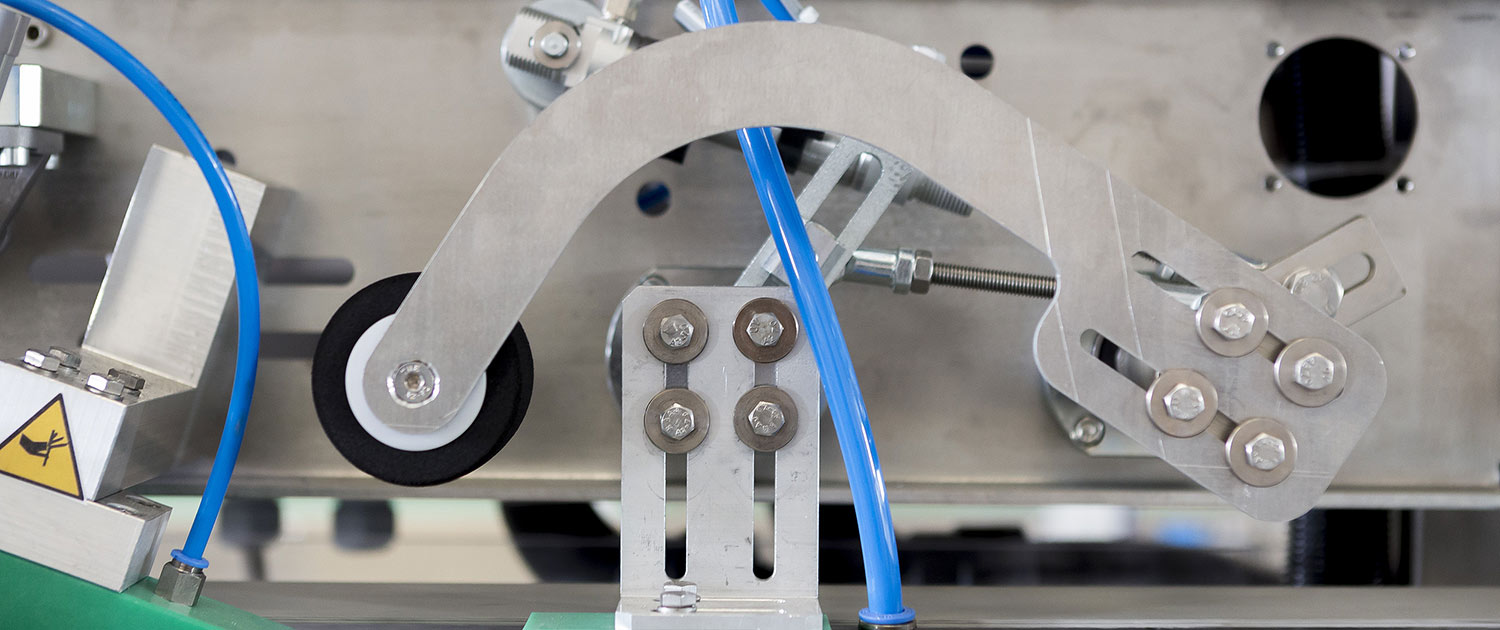

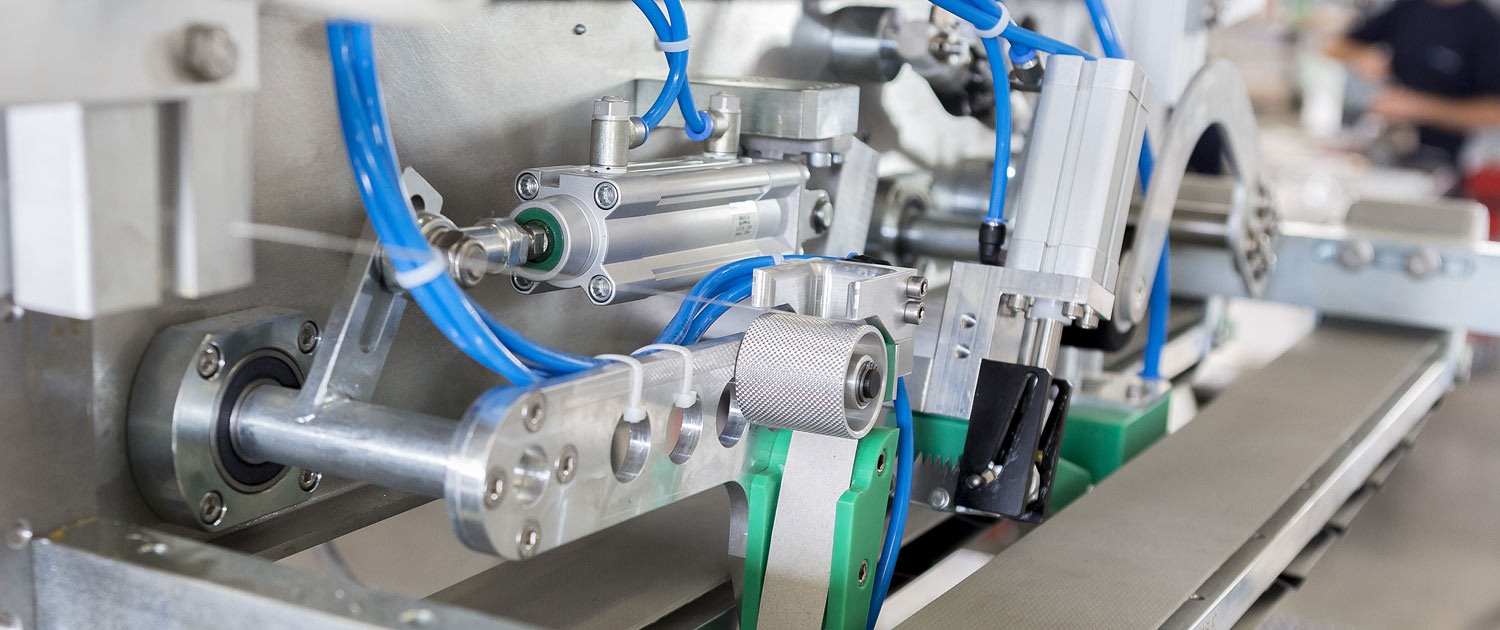

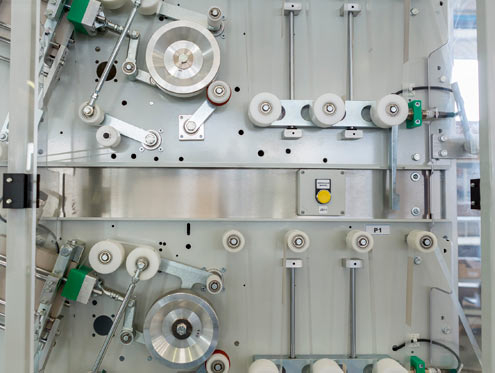

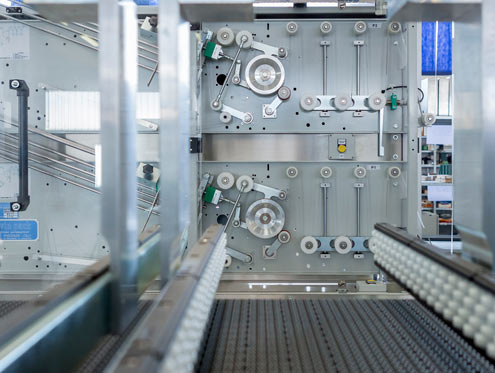

On each track the packs arrive on the machine infeed conveyor, and are then automatically slowed down and spaced via a series of Intralox conveyors. The adhesive tape is unwound by an electronically controlled motor-driven roller as a function of pack flow. Application of the cardboard (or other materials) on the adhesive is carried out continuously by a mechanical double cam system. The thus-obtained handle is applied to the transiting cluster by a continuously moving set of pneumatically operated arms.

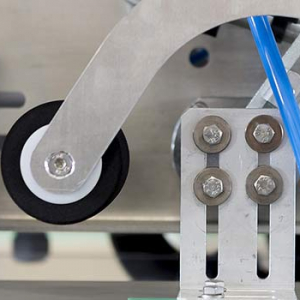

Cutting of the adhesive tape is performed by a unit with a cam-guided blade. The machine PLC oversees and controls the whole cycle and ensures proper repetition of movement.

The machine can also be equipped with a mechanical device (optional) that gives the handle an arched shape, a must on certain products. Handle and cardboard alignment is electronic, allowing the machine to correct any errors autonomously via automatic repositioning.

The handle tape is made of transparent mono-oriented polypropylene coupled to the cardboard (or other materials), which may be plain, coloured or printed with promotional text and/or images. Each head can be provided with a second reel holder for 5000-metre adhesive tape reels. All machines can work with pre-laminated adhesive tape reels.

Our machines can manage different types of handles:

- cardboard handle and adhesive tape and the two materials are joined by machine

- handle with pre-labeled adhesive tape, the already unwound handle complete with the two materials

- soft touch handle, with adhesive tape and handle called “mousse”, the two materials are joined by machine

TECHNICAL FEATURES

Min-Max speed in single line: da 35 ppm a 85 ppm

Min-Max speed in double line: da 35+35ppm a 85+85 ppm

Min-Max speed in triple line: 85+85+85 ppm

MODELS

The standard handle applicators are grouped into three categories, each of them divided in different machine models, depending on the line speed.

According to the technical features of the customer’s line we propose the machine that best suits the technical requirements of the project.

Standard single lane handle applicator

Working range from 35 to 85 packs per 1′

Standard double lane handle applicator

Working range from 35+ 35 up to 85 + 85 packs per 1′

Standard triple lane handle applicator

Working range from 35 + 35 + 35 up to 85 + 85 + 85 packs per 1′

DOCUMENTATION

PHOTO GALLERY