DESCRIPTIONS

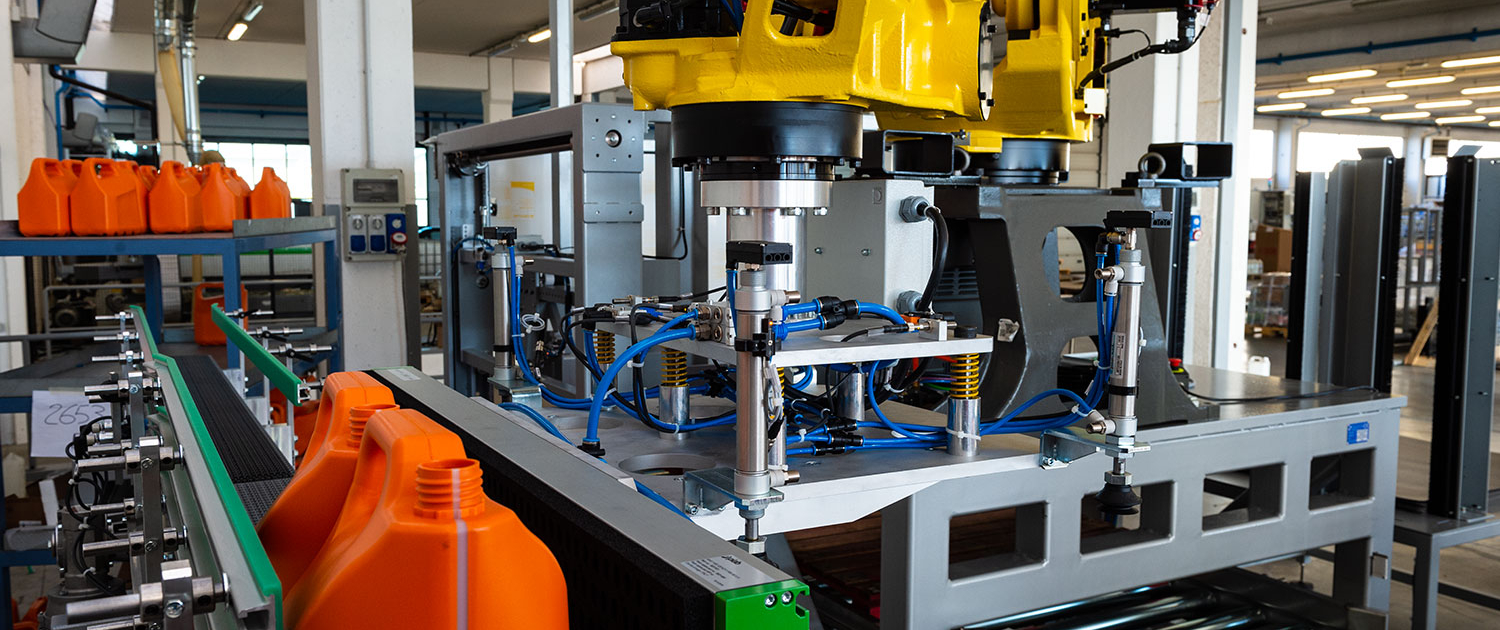

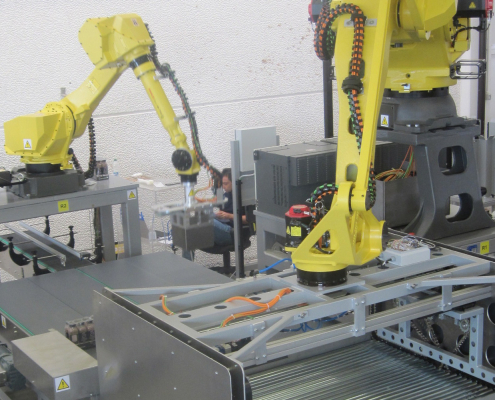

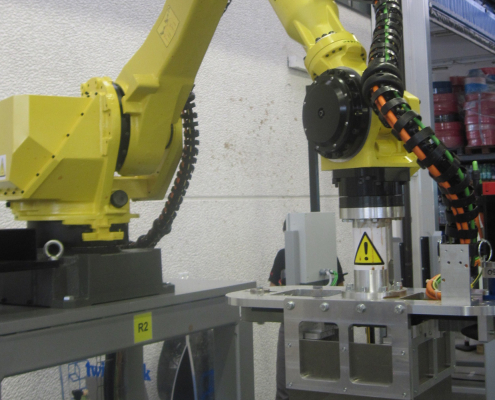

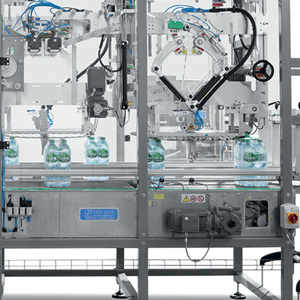

The central structure in painted steel, is sturdy and rigid, which allows a safe anchoring of the Robot to the floor with chemical tassels.

According to the palletizing scheme, the preparation of the products takes place through different handling systems for the single, multiple and / or complete layer picking of the Robot, and can be carried out using mechanical packs orientation devices or through the use of special robots.

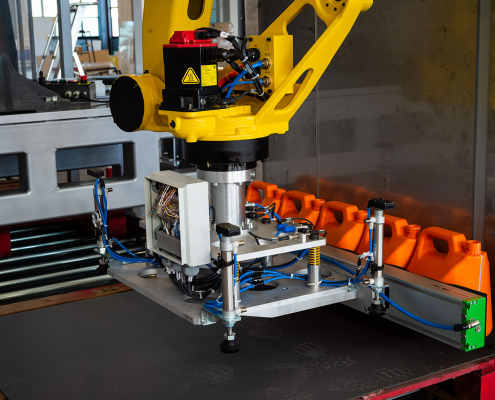

The positioning of the products on the pallets is precise, fast and accurate thanks to the kinematics of the brushless rotary axes (4, 5 or 6 axes).

The palletizing scheme can be prepared by customized handling systems according to the line speed and the picking to be carried out:

- for single or row product picking. The preparation can take place through mechanical packs orientation devices

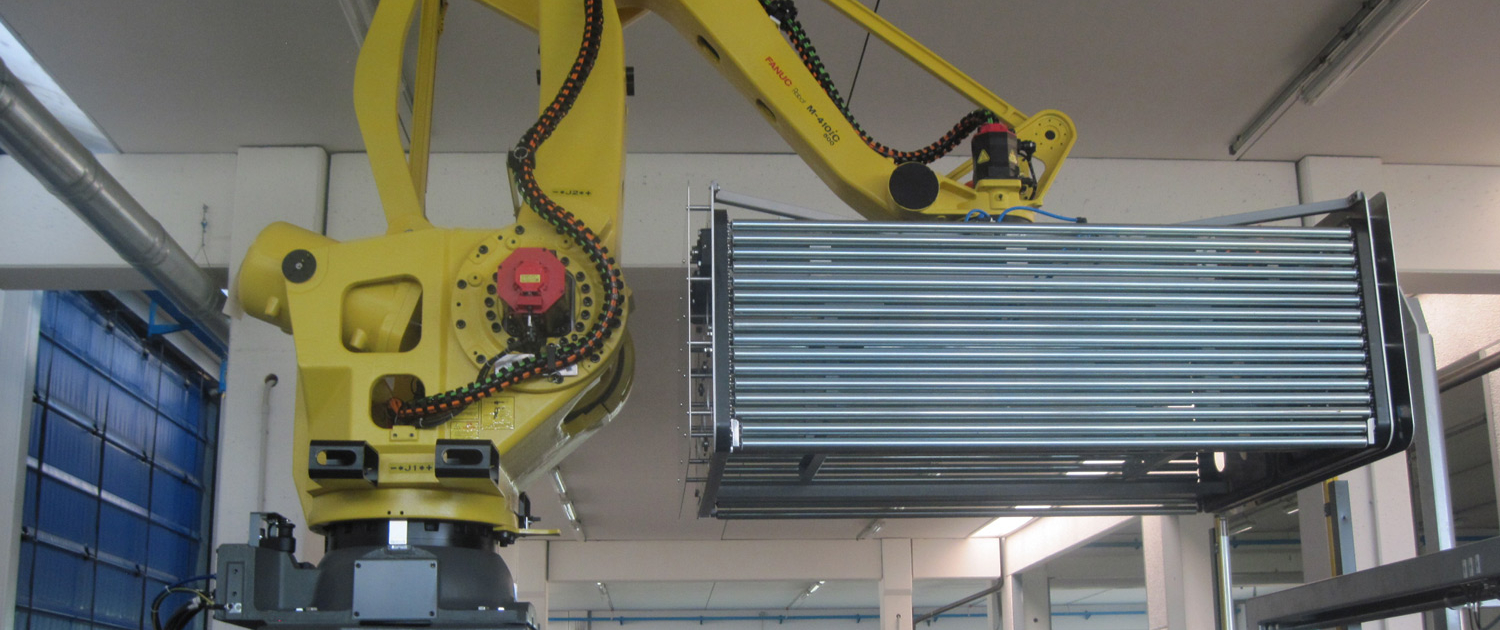

- for full-layer picking. The preparation can be mechanical or robotic in tracking mode

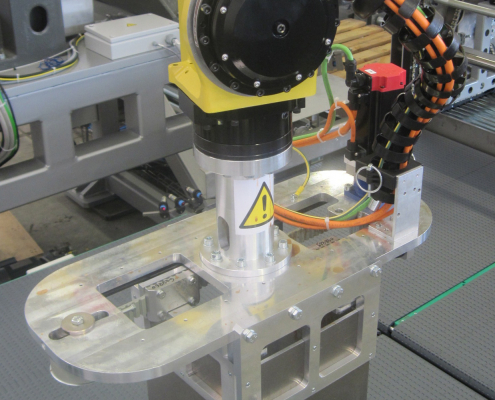

The Robot Picking Head is specially designed according to the specifications of the product to be handled:

ex. multiple self-adjusting gripping head, with suction cups device (for single pack, multiple or row picking), “Venetian blind” picking head (for full-layer picking) etc.

Moreover, the same head can be equipped with ad-hoc devices both for the picking and depositing of the layers between one layer of products and the other, and can be used for the picking and depositing of the empty pallets from the dedicated roller magazine.

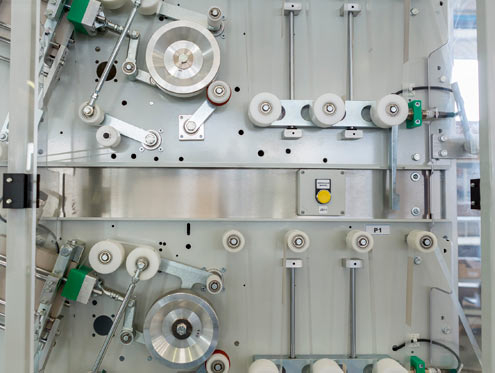

According to the palletization needs and speed, it is possible to add to the line an automatic interlayers module.

TECHNICAL SPECIFICATIONS

Robot head rotation: up to 360 °

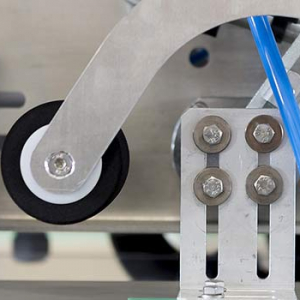

Motorized transports, roller or chain, for the exit of full pallets.

Optional supply of automatic empty pallets magazine, up to 15 units.

Latest generation Twin Pack software

Programming and access by password or special key

Control unit integrated in the electrical cabinet

Safety parameters according to CE standards